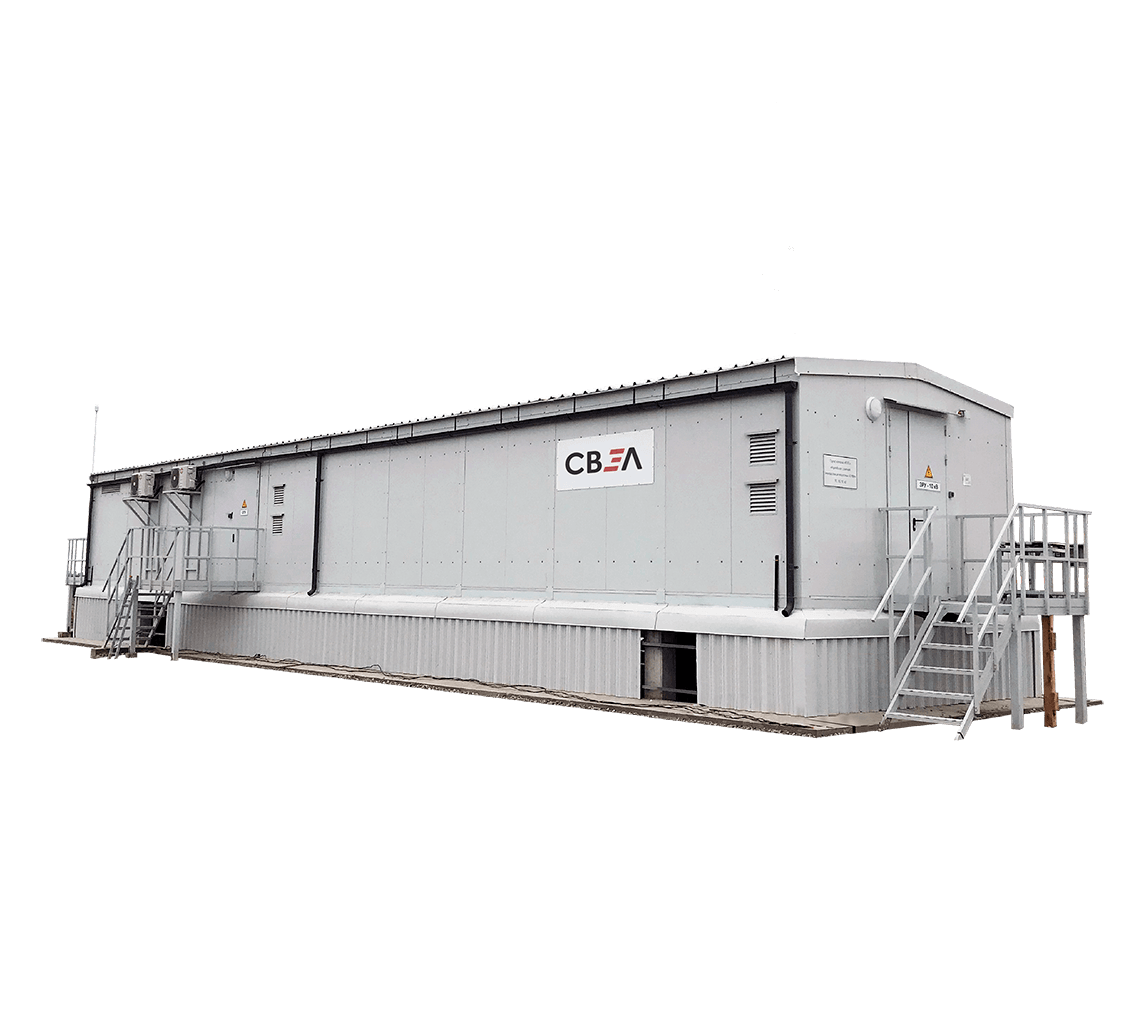

Description

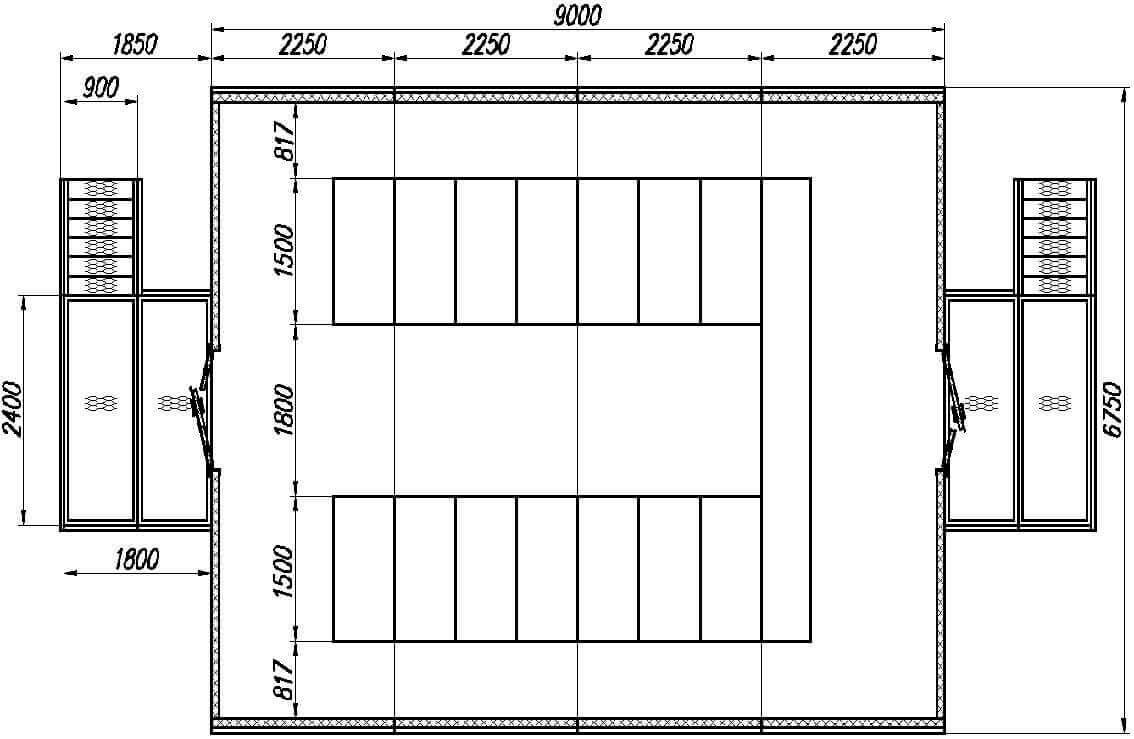

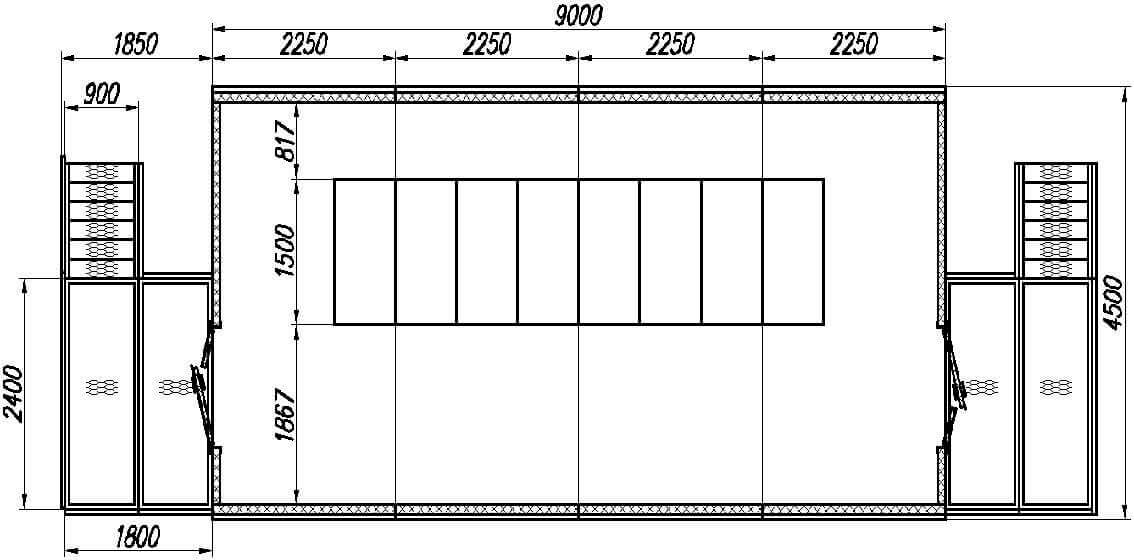

E-House is made of several interconnected modules on the common foundation to form a single-space location. Its layout as well as the mounted systems and auxiliary equipment allow creating the necessary conditions for the normal operation and maintenance of power equipment inside the E-House.

E-House with Switchgear is used at the altitude up to 1,000m above the sea level under the boreal climate, environment class 1 as per GOST 15150-69 and ГОСТ 15543.1-89, subject to the following climate conditions:

- Max Ambient Temperature +40°С;

- Min Ambient Temperature -60°С;

- Design Indoor Air Temperature at least +5°С

- Relative Humidity 75% at +15°С (annual average);

- Atmosphere II, Industrial

The external impact factors are applicable for М13 mechanical configuration, as per GOST 17516.1-90 (2001).

Seismic Strength up to 9 (MSK-64).

Operating values of mechanical load and impacts:

- permitted snow cover load up to 3,200Pa;

- wind speed up to 36m/s, wind dynamic pressure up to 800Pa;

- thickness of ice up to 20mm.

Technical Data

Normally, the equipment and systems for mounting inside of the E-House is selected upon customer’s data sheet, and, as a rule, these include the following:

E-House:

- Several modules (as per customer’s request), delivered with the mounted equipment. The modules are made of frames with heat-insulated walls, floors, ceiling, and a gable roof plated with at least 2mm thick steel sheets. Heat insulation is ensured with at least 100mm thick mineral wood boards. Internal coating of the roof is light-colored, mostly white. The module’s walls are made of 100mm thick ‘sandwich’ type wall panels. Internal coating of the walls is light-colored, mostly white. To mount the attachments, all walls are equipped with the 2mm thick built-in steel sheets. Special openings are provided for mounting vent equipment on the walls. Externally, each opening has a shield to protect vent system from precipitation or ice. A loop-circuit earthing device is provided inside of E-House.

Auxiliary systems that ensure proper operation and maintenance of E-House includes the following elements:

- Lighting;

- Heating;

- Ventilation (natural or forced).

To ensure power supply of the auxiliary systems, E-House may be equipped with auxiliary transformer (upon request). Normally, one or two three-phase, up to 63kV∙A, inclusively, voltage class 6(10)/0.4kV, auxiliary transformers are mounted into the switchgear cell in a separate insulated shell. Generally, power supply can be ensured both by an auxiliary transformer installed in the switchgear, or two external separate sources.

- Additional equipment upon customer’s request may include various systems and instruments, such as:

- Security and Fire Alarm (remote monitoring of unauthorized access and fire);

- Uninterruptible Power Supply, DC (continuous operation of the relay protection, control, alarms, etc.), or Trip Supply Cabinet;

- Transceiver System, or Marshaling Cabinet (collecting and transfer data on power and auxiliary equipment to Control Board) ;

- Outside lighting control system (lighting of substation platform, access roads, security lighting. etc.)

- and others.

Power Circuit:

- Switchgear;

Power equipment for E-House with Switchgear is made on the basis of standard switchgear by SVEL comprising the separated switchgear cells. Number and type of cells is determined by customer’s request. Also, upon request, we can add other switchgears of various types and brands, or prepare any applicable tailored solution. Here all the technical details are referenced on the standard switchgear by SVEL.

- Connecting Conductors;

For E-Houses with dual-in-line power equipment arrangement, to connect current conductors of the opposite cells, a busbar bridge is applied. The Busbar Bridge has reduced dimensions to fit into the module of E-House. The Busbar Bridge is a system of plain busbars in the steel casing located on a side panel of switchgear cells line. The Busbar Bridge casing is equipped with pressure relief valves in case of inside arcing.

The Busbar Bridge can function as a combined busbars arrangement or a jumper.

- Busbar;

Switchgears inside of the E-House can be equipped with busbar bushings outgoing through the E-House wall. The busbar bushings are intended for receipt of AC three-phase power, rated voltage 6kV or 10kV, 50Hz at the overhead lines, main busbars, or directly at a power transformer (plain busbars or clamped conductors)

- Overhead Connections.

E-House with Switchgear can be equipped with an overhead bushing to receipt AC three-phase power, rated voltage 6kV or 10kV, 50Hz at the overhead lines. The overhead bushing is an electrical unit that assembled and mounted into the operating position on-site. Structurally, the overhead bushing includes the following elements:

- Base Frame (bearing support);

- Cable Jumper (current conductor between the overhead line and switchgear, which is ensured by a single wire cable type APvVng 1х240/25-10, with the max load up to 630A);

- Protective Casing (to cover Cable Jumper at the height of 2m from the E-House level;

- Earthing Bar (to connect earth of the overhead component to the common earthing circuit);

- Rigid Insulators with contact platforms (to connect cable jumper of the overhead bushing and clamps);

- Lugs (to fasten the hauling rope of overhead line, permitted total tensions of three ropes less than 500kg).

Upon customer’s request, the additional elements can be mounted on the overhead bushing, such as:

- Surge Arresters (lightning and industrial surge protection);

- Pulse Register (applicable together with surge arrestors, or by additional contact to transmit signal to the alarm system).

Metal structures:

- Foundation Frame;

- Fenced Service Platforms;

- Protected Flight of Steps.

-СВЭЛ 1.jpg)

-СВЭЛ 2.jpg)

-СВЭЛ 3.jpg)