Description

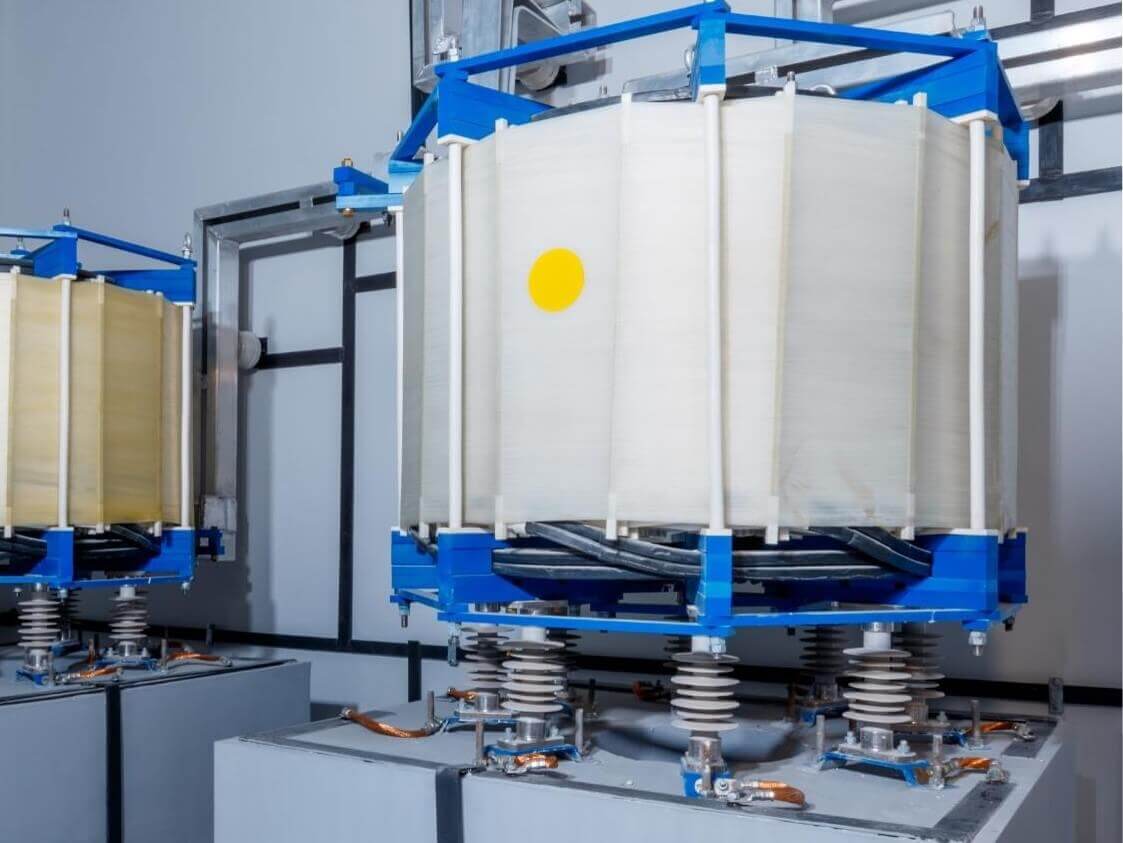

Over 15 years, SVEL Group designs and manufactures Dry-Type Current-Limiting Reactors with air-core. Therefore, many customers highly evaluate reliability and cost-efficiency of our products. More than 22,000 various reactor units are currently operated, that confirms the implicit leadership of SVEL Group.

Substantial investments in unique design patented by numerous patent licenses allow manufacturing reactors with minimal overall dimensions and weight. SVEL Group is well known for their state-of-art products that ensure reduced capital and operating costs of our clients.

Advantages

Upon the experience of operating reactors manufactured by the global leaders, SVEL developed own innovative design with the following apparent advantages:

- high mechanical strength and shock resistance

- double insulated conductor

- properly fastened conductor, free from any loose sections

- all conductors connections arranged beyond the reactor’s body

- reliable protection from UF, precipitation or dirt

- minimal loss and low noise

- welded electrical connections

Types of equipment

Product range:

One-piece and two-piece reactors

- single-phase

- three-phase vertical

- three-phase angular (stepped) configuration

- three-phase horizontal

Optionally, the following items may be added to the delivery scope:

- stainless steel pole (to ensure proper distance)

- bus compensator

- support metal structure

- porcelain insulator (polymer insulator delivered by default)

- e-house for reactor

- technical supervision and installation monitoring

Technical data

Main Parameters*:

| Parameter name | Value |

|---|---|

| rated voltage, kV | 3, 6, 10, 15, 20 |

| Rated Current, A | 50 - 10 000 |

| Inductance, Ohm | up to 50 |

| Climate configuration | temperate, boreal, cold, tropical |

| Environment class | 1, 2, 3, 4 |

| Angle between terminals, ° | 0, 90, 180, 270 |

* Upon customer’s request, optional parameters are considered.