Dry-Type Cast Resin Transformer Production Site

Year of Commissioning: 2003.

Capacity: 3,000MVA/Year.

Our Products:

- Power Distribution Transformer 16kVA to 3,200kVA

- High-Power Transformer 4,000kVA to 25,000kVA

- Auxiliary Transformer for power plants and other facilities

- Power Transformer technical control cells 25kVA to 63kVA

- Power Transformer, earthquake-proof and vibration-and-mechanical resistant

- Transformer for Wind Farms

- Power Transformer with OLTC

- Power Transformer with amorphous steel core

Power efficiency of dry type transformer

SVEL Group offers distribution transformers with various loss level: from Class А (power efficient) to Class С (regular loss level).

All SVEL transformers, regardless their power efficiency level, demonstrate consistently high reliability and overload capacity.

Reactor Production Site

Year of Commissioning: 2004.

Capacity: 2,000phases/Year.

Our Products:

- Dry Type Current Limiting Reactor 3kV to 20kV

- Dry Type Current Limiting Reactor 35kV to 500kV

- Shell-Type Reactor

- Starting Reactor

- Smoothing Inductor

- Line Trap

- Filter Reactor

- Damping Reactor

- Compensating and Shunt Reactor

Advantages of Reactors by SVEL

Extended product line

- 50A to 10,000A, Voltage Class up to 500kV;

- A wide range of reactors.

Own patented technologies

- Small footprint and low weight;

- Flexible layout of terminals;

- Reactors with reduced loss.

State-of-industry insulation and components

- Insulation materials – Heat Resistance Category Н

- Polymer insulators

Fast shipment

- Manufacturing cycle of Dry-Type Current Limiting Reactor – 20 to 45 days.

Oil-Immersed Transformer Production Site

Year of Commissioning: 2009

Capacity, at full load: 24,000MVA/Year

Our Products:

- Power Transformers for Grid Substations and Industrial Facilities;

- Autotransformers;

- Generator Transformer;

- Auxiliary Transformer;

- Transformer for iron and steel productions;

- Furnace Transformer;

- Transformer for Railway Substations;

- Line Regulating Transformer.

Instrument Transformer Production Site

Year of Commissioning: 2010

Capacity: 8,000pcs/Month

Our Products:

- Voltage Transformer (VT);

- Current Transformer (CT);

- Power Transformer.

Advantages of Instrument Transformers by SVEL

- Customized solutions

- Non-standard parameters, by request

- Reduced delivery time

- Emergency protection

- Saving due to reconstruction of substations

- Reduced stock of components for switchgears

- Continuous extension of product range, and increase of production capacity

HV Equipment Production Site

Year of Commissioning: 2011

Advantages of Disconnectors by SVEL

- Vertical or horizontal mounting on a rigid busbar;

- Zero maintenance;

- Simple and fast installation, on-site;

- Secure lock of the main and earthing knives of disconnector and earthing devices at the end operating positions;

- Reliable operation of disconnector even at icing;

- Strong protection from human error;

- Solid base for disconnector’s pole and rotating anvil;

- Zero corrosion within the whole operation cycle.

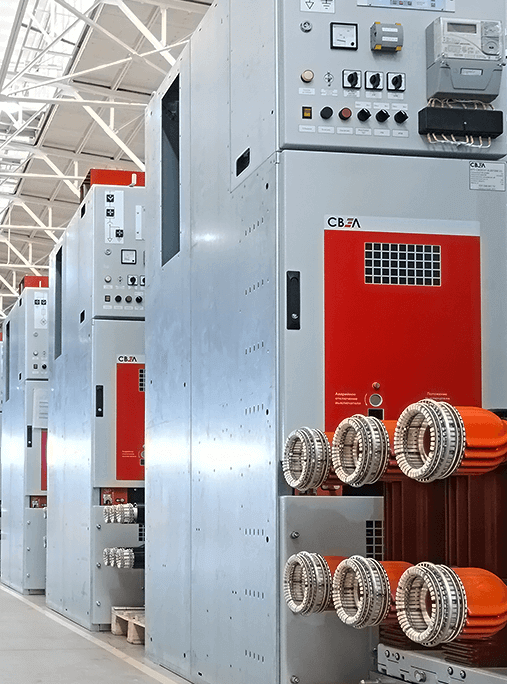

Switchgear Production Site

Year of Commissioning: 2009

Capacity: 2,000pcs/Year

Our Products:

SVEL Group offers an extended product line of switchgears series SVEL 6(10)kV, 35kV for various applications. We always focus on high-level of safety, reliability, and simple design solutions proved by the comprehensive testing.

Switchgear cells can be equipped with a set of digital devices that ensure proper functioning of relay, automated, metering and control equipment, comprising SCADA as per the international protocol IEC 61850.

Transformer Substation Production Site

Year of Commissioning: 2009.

Capacity: 500pcs/Year.

Advantages of Transformer Substations by SVEL

- Prefabricated structures, a wide range of possible configuration;

- Minimum welds, galvanized steel sheets;

- Flexible design and quick replacement;

- Maximum operational readiness;

- Applicable for outdoor operation, inside of E-House;

- Compatibility with Dry-Type Cast Resin Transformers relieves from the need to establish and maintain an oil facility;

- Fit for any type of foundation, Seismic Strength up to 9 (MSK-64).

Packaged Integrated Transformer Substation Production Site

Year of Commissioning: 2011

SVEL Group enjoys all necessary resources and competencies to implement end-to-end complex projects: from design to commissioning.

SVEL equipment allows you to cover 80% of the needs for products to ensure transmission and distribution of electricity.