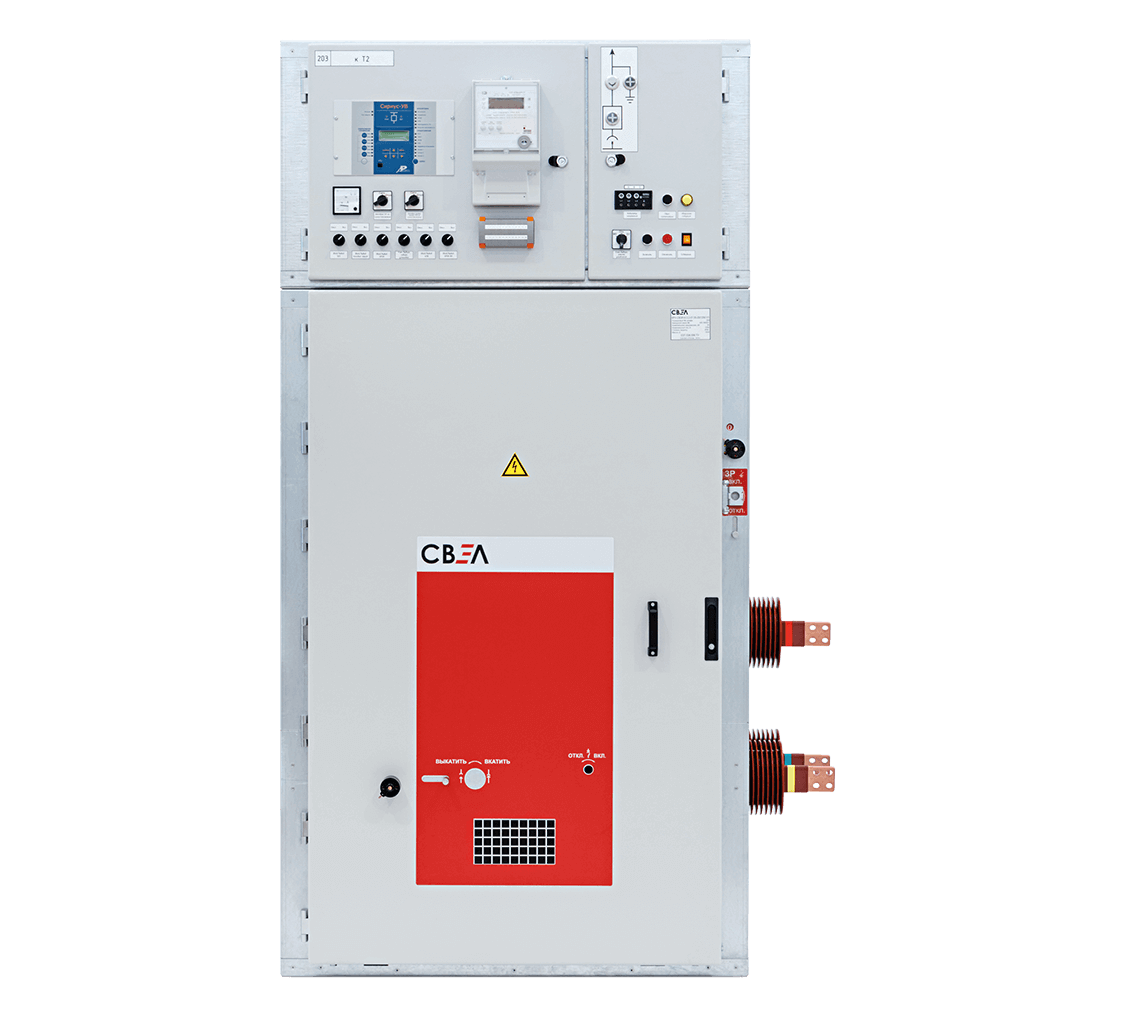

Description

Switchgear Cell Type SVEL-K-3.2 is designed for indoors operation under the following conditions:

- Altitude - up to 1,000m, asl;

- Max Ambient Temperature +40°С;

- Min Ambient Temperature -25°С;

- Relative Humidity 75% at +15°С;

- Environment Class - II Industrial, as per GOST 15150;

- Non-explosive media, free from any current conducting dust, aggressive vapors or gases that can destroy insulation or metal.

- Switchgear cell type SVEL-K-3.2 are installed into an e-house (packaged modular facility) equipped with heat and vent systems.

- The Switchgear meets the requirements of GOST 14693, GOST 12.2.007.0, GOST 12.2.007.4.

Application

Single-side Service Cell, SVEL-K-3.2 is applied at numerous industries:

- Oil&Gas

- Power Industry

- Ferrous&Non-Ferrous

- Engineering

- Chemical

- Petrochemical

- Infrastructure

- Agriculture

Advantages

Key advantages of Switchgear Cell Type SVEL-K-3.2 vs. Switchgear Cell Type SVEL-K-3.1:

- Single-side service;

- Depth, less by 500mm;

- Bottom busbars.

Competitive Advantages:

- All operations are accessible at the front side of the cell, with the door closed;

- Easy access to the built-in CTs and VTs;

- Excessive Pressure Release ensures personnel safety, in case of emergency;

- Max Rated Current up to 2500 А;

- Patented Design of Door Lock for Compartments with Enhanced Security;

- Patented System of Easy and Smart mechanical and electrical interlocks;

- Service Life - 30 Years;

- High Level of Environment Resistance;

- Quick Earthing Disconnector with Spring Drive;

- Upon customer’s request, drawout element and earthing disconnector can be equipped with a motor drive for remote control;

- Flexible modular configuration ensure easy integration of any component, upon customer’s request;

- Drawout Element with ultra-proof strength confirmed by testing;

Design

The frame of Switchgear Type SVEL-K-3.2 is made on a high precision cold forge equipment out of a high quality steel sheet with anti-corrosion aluminum-zinc coating. Front elements (doors, covers) and side panels are made of carbon steel and coated with the polymer powder coating.

The cabinet has ventilation holes to ensure the normalized cooling of the main current-carrying circuit.

The drawout cable compartment contains heating elements, which are switched on automatically at temperatures below minus 5 °C.