Description

Small-Size Switchgear Cell Type SVEL-K-1.3 is designed for indoors operation under the following conditions:

- Altitude - up to 1,000m, asl;

- Max Ambient Temperature: +40°С;

- Min Ambient Temperature -25°С;

- Relative Humidity 75% at +15°С;

- Environment Class - II Industrial, as per GOST 15150;

- Non-explosive media, free from any current conducting dust, aggressive vapors or gases that can destroy insulation or metal.

- Small-Size Switchgear Cell Type SVEL-K-1.3 are installed into an e-house (packaged modular facility) equipped with heat and vent systems.

- The Switchgear meets the requirements of GOST 14693, GOST 12.2.007.0, GOST 12.2.007.4, and GOST Р55190.

Application

Switchgear Type SVEL-K-1.3 is applied at numerous industries:

- Oil&Gas

- Power Industry

- Ferrous&Non-Ferrous

- Engineering

- Chemical

- Petrochemical

- Infrastructure

- Agriculture

Competitive advantages

- Small size vs. maintained insulated compartments and easy and comfortable cable connections

- Excessive Pressure Release ensures personnel safety, in case of emergency;

- Patented Design of Door Lock for Compartments with Enhanced Security;

- Patented System of Easy and Smart mechanical and electrical interlocks eliminates possible human errors;

- Service Life – 30 Years;

- High Level of Environment Resistance;

- Quick Earthing Disconnector 3P-10 with Spring Drive;

- Upon customer’s request, drawout element and earthing disconnector can be equipped with a motor drive for remote control;

- Drawout Element with ultra-proof strength confirmed by testing;

- Patented Status Indication Method of Drawout Element and Earthing Disconnector;

- Easy maintenance of the built-in CT located on a quick mounting panel; and

- No additional support is required for maintenance of the relay cabinet.

Design

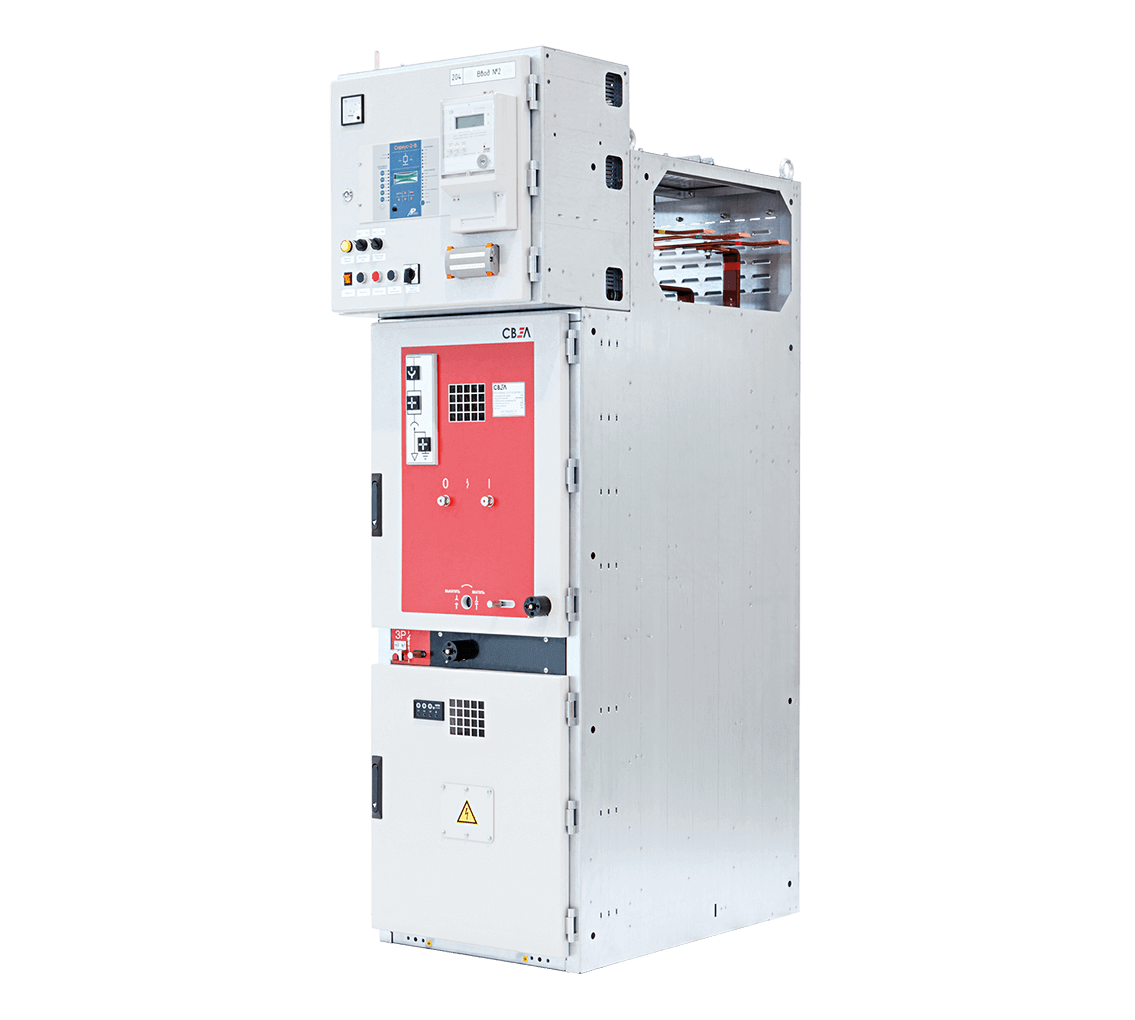

Small-Size Switchgear Cell Type SVEL-K-1.3 is a compact model of Switchgears by SVEL, rated voltage 6(10)kV, and operating current of 1,600A.

The frame of the Switchgear is made on a high precision cold forge equipment out of a high quality galvanized steel. Outside elements (doors, side panels, etc.) are coated with the powder paint material that ensure high-level anti-corrosion protection within the ambient environment.

The compartments are divided by the removable metal partitions that ensure reliable mitigation of an arc fault sequences within a single compartment. No welded joints are used, and all elements are pivot-fixed. To ensure protection of the operating personnel, the doors and shutters are equipped with the special locks of the patented design, preventing the release of arc combustion products towards the operator.